Off 20 N of Aiken, SC there is an abandoned historic textile mill for sale and I went in 2016 with Jim and Will Brennan to assess and meet with a potential developer. It is 130,000 sf and has 26 million gallons of spring water hydro generation but will take 2 million dollars to restore the hydro turbine (Jim’s advisor suggested). Scott- Hydro- Ridgeway;

Jim had discussed our plan with Phillips and received a quote “Green sense” LED Lighting Proposal.

25,000 SF – 18′ tall;

100,000 SF of Growing Surface will produce 1.4million # of lettuce @ $2/#

Carleton and Gizman met with us and we walked through together.;

We would want to sell in loose RPCs;

Christian Long at Current Cultures H20 and I discussed in Fresno CA the UCPRO20, 22-site set down the middle of the container or in two rows along the outside walls. 12/9/16, email from Christian to Warren quoted that the Lids are interchangeable for multiple plant spacing and size options. Rough commercial pricing on this system is around $7k. They could also offer a 32-site, 2 rows 13-gallon system (XL13) for around $4200, attached is a drawing of the 24-site “Long Rifle”. Check out other commercial layout options sheet with pricing.

Equipment & Tools

We plan to work closely with Hort Americas for Hydroponic Fertilizer

They sell a 9-7-37 Hydroponic Fertilizer. It is specially formulated for growing leafy green, culinary herbs, microgreens and other crops in a hydroponic system. Hort America has designed this water-soluble fertilizer to deliver the essential nutrients for optimum uptake by the root system. It can be used as a constant feed or as a supplement. Hort Americas recommends that the grower have their source tested by a professional water analysis laboratory to determine the nutrients, pH, EC and total alkalinity of your source water.

Suggested Rates: .271-.455 lbs./100 gallons of water

1.23 to 2.06 grams/1 gallon

Sold in 25 # containers

General guidelines for hydroponic crop production: maintain a pH between 5.4 and 5.8 with an EC of 1.5 mS/cm once the cotyledons have fully expanded. (trademark “Cotyledon Containers”) have fully expanded.; derived from Potassium nitrate, Monopotassium phosphate, sodium borate, copper, iron, manganese, and others

Hort America recommended we use NFT and if we go organic, use their “Closed Bottom Organic Plugs”- hold the roots more and when combined with Terragenesis Organic Fertilizer for hydroponic systems, we theorize that you will see far fewer issues with the oversized roots clogging up the system (as Warren experience during his 6th hydroponic crop at Pelion Highschool.

we designed a system 5 feet wide and 12 feet long/ 5ft LED lights;

Germinating: the process of germinating is pretty simple and will only require a small table off to the side that can accommodate 6-8 of the 10×20″ trays.

We will wet/soak the media, seed and then cover them with a humidome to generate humidity. You may want to use a heating mat for the cilantro, as it requires a lot of humidity to germinate.

To prevent light contamination while germinating, we plan to cover them all on the table with a sheet.

Once they start to pop, we uncover them and place them in a propagation channel where they can be fully lit and fed with the propagation tank. Once the roots develop and begin breaking out of the cubes, they move to the nursery channels and once they fill out enough, they go up to the finishing channels where you can harvest from.

Rockwool is not organically approved- cilantro requires so much humidity to germinate, generally we could use a higher water holding material like rockwool.,

Coco is organic OMRI approved, made from Coconut biproducts.

The LEDs will be run 20 hrs./day to get the amount of light to the plants they will need, and they should grow quick.

Their racking needs room for a 5′ wide x 12′ Long x 12′ high,

Two water tanks for propagation and nursery/finishing

and a Table for germinating roughly 3×5′. We will want about 3-4′ of space around the racks to maneuver and harvest

Company Overview: Ownership & Structure

Matt & Will Brennan visited Clark Atlanta University.

Attendees were: Dr. Johnson, President of the University

MaryLynn- Harvard MBA, Wall Street Ex

Dr. Dunell Taylor- Integrating Sustainability

Dr. Roy George- Computer Science Department

Dean of the Business School

Dr. Chaudhary- Associate Dean

Dr. Platt

Interested in Solar Bots

Lots of discussion around the book, The Vertical Farm.

Watertronics

Immigration reform issues

Sodexo- food supplier to the university

they don’t have a foundation

timeline and schedule of the school was slow;

My goal with the school trial model was to:

- Build the business model

- Track Labor rates and job details commercially

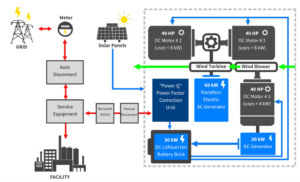

- Figure out lighting, HVAC, and other electricity costs or panels needed;

Double ended fixtures- “the most widely used” 30% brighter than traditional lights; HID lighting : blue and red; 1000 w are traditional =>for 25 SF; Phillips Lighting would work with us as a trial; need to know PAR values; LEDs; Power and heat in 1/2

Traditional lighting – highboy fixtures

Call Ricky Espinosa for HVAC

Traditional Air-Cooled Fixtures

Water testing for our systems would be done on a once per month basis and sent off to Microbac or other 3rd party lab for food safety audits.

We can stack 3 containers (said freight farms; weights 7.5 tons; can run off a generator 10kw

they use Zip grow 256 zip grow towers

we need a drain tank

Agriteck

2″ pitch in the back of the container

the recordings of water system are in an app

Baby kale is not big kale

1 container 15-20 hrs./wk.

3 harvest kale and cilantro

organic mini-sized butterhead lettuces

bumper to bumper 1-year warrantee – $50 maintenance per month.

It would be interesting to see what kind of patents these freight farms companies have and what is publicly readily available to replicate

one unit uses 35,000 kwh / yr.

$85,000 – includes filtrations and dehumidify,

50,000 hrs./ LED;

COB- Chip on board lighting

Wastewater must be dealt with appropriately and with property documentation

chiller and water circulation

stress training – stressing the plants to train them to perform as needed (tricked to bloom by stressing)

Reduce the nodes by 10-15% reduction in yield;

Temperature and nutrients have been figured out by Ari and Paul with Freshly Grown Farms

Identify a Crop Specialist to manage

Excel in Agri-technology

try and see if organics can be grown mass market

Help determine markets for Coyotes based on location of demand

Have cameras set up to monitor and security

determine yields

develop curriculum

Matt traveled to Fresno California and met with partners of Current Cultures H20= they use 2-3″ PVC; look at the different diagrams and choose; Food grade plastics, 3, 13, 35 plants per top. Schedule 40 pipe; multiple lids; 35 neck cups;

Bloom rooms are set up differently from Veg room based on ___

change the temperature and there is less dissolved oxygen

spider mites, root aphids, and Botrytis, keep humidity less than 50%.

Predator mites are beneficial insects. Release the predatory mites.

Azamax – which is an oil/ apply weekly or biweekly to the crop

UV light in the water system;

Ozone and Ozone generator are needed:

Freshcut room for sterile harvesting with positive draining

Call WPRawl’s Wastewater Expert, Michael Geronomicous about wastewater

Three important elements: AC/ Heat/Dehumidifier;