In an effort to help promote the expertise of our President and Chemical Engineer, I complied many key phrases and subjects dealing with chemical incidents. In no particular order and without the expert’s approval or “stamp on it”…below are my thoughts and research for the day.

Personal Protection and Sanitation Codes

Chemical Casualties Handbook- Medical Management of Chemical Casualties. Poisoning by (ie, exposure to) toxic chemicals, a process also called intoxication,

Symbols, Code Components, and Codes Used for Respirator Selection

Selection of N-, R-, or P-Series Particulate Respirators

Abbreviations for Exposure Routes, Symptoms, and Target Organs

Codes for First Aide Data

Chemical listing

Potential Occupational Carcinogens

Thirteen OSHA-Regulated Carcinogens

Supplementary Exposure Limits

Substances with No Established RELs

OSHA Respirator Requirements for Selected Chemicals

Chemical, Synonym, and Trade Name Index

“TWA is the employee’s average airborne exposure in any 8-hour work shift of a 40-hour work week which shall not be exceeded.” The 8-hour TWA PEL is the level of exposure established as the highest level of exposure an employee may be exposed to without incurring the risk of adverse health effects. https://www.osha.gov/laws-regs/standardinterpretations/1995-10-06-3

Permissible Exposure Limits – Annotated Tables https://www.osha.gov/dsg/annotated-pels/

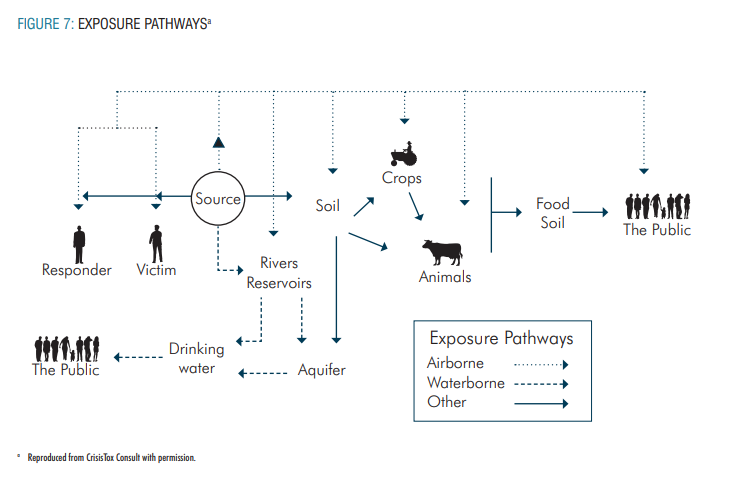

Exposure Factors: Soil and Dust Ingestion https://www.epa.gov/sites/production/files/2018-01/documents/efh-chapter05_2017.pdf

Each year in the United States, many thousands of workers are made sick from chemical exposures, and the long-term effects of chemical exposures in the past are believed to cause as many as 50,000 deaths annually, according to the Occupational Safety and Health Administration. Over the years, NIEHS Worker Training Program (WTP) staff and awardees have explored a variety of topics related to chemical hazards and risk, with a particular focus on protecting workers from exposure to hazardous chemicals through the use of effective training approaches. This page provides safety and health resources on issues such as chemical hazard identification and assessment, chemical safety and security, and chemical incident response. https://tools.niehs.nih.gov/wetp/index.cfm?id=244

Paint strippers containing methylene chloride

have been associated with 13 fatalities to

bathtub refinishers since 2000. ©2016 Earl Dotter

How will the changes to the Toxic Substances Control Act (TSCA)

impact workplace chemical safety and health? What is TSCA? TSCA is the “Toxic Substances Control Act” of 1976 that gave the US Environmental Protection Agency (EPA) the authority: “to regulate chemical substances and mixtures which present an unreasonable risk of injury to health or the environment”.1

TSCA provides EPA with authority to require reporting, record-keeping and testing requirements, and restrictions relating to chemical substances and/or mixtures. Certain substances are generally excluded from TSCA, including, among others, food, drugs, cosmetics and pesticides.

Why was TSCA amended and updated?

People concerned with chemical safety and the EPA itself have long considered TSCA outdated and ineffective in protecting people from dangerous chemicals. Even asbestos, with its record of killing more than 10,000 Americans every year, could not be restricted under TSCA. In 1991 the federal courts ruled that TSCA did not give EPA the power to ban

asbestos. Subsequently, EPA stopped using the law to restrict chemicals.

On June 22, 2016, President Obama signed the Frank R. Lautenberg Chemical Safety for the 21st Century Act, which updates and amends the TSCA, including its impact on workplace chemical safety and health.

What is the current state of chemical regulation in the workplace?

Under the Occupational Safety & Health Act, OSHA is the federal agency responsible for establishing and enforcing national safety & health standards. However, OSHA has acknowledged that limitations on its authority are preventing it from using the most current evidenced based chemical exposure limits in regulating workplace chemical exposures.

From the OSHA website:

“OSHA recognizes that many of its permissible exposure limits

(PELs) are outdated and inadequate for ensuring protection of worker

health. Most of OSHA’s PELs were issued shortly after adoption of the Occupational Safety and Health (OSH) Act in 1970, and have not been updated since that time. Section 6(a) of the OSH Act granted the Agency the authority to adopt existing Federal standards or national consensus standards as enforceable OSHA standards.” Most of the current PELs were based on the 1968 Threshold Limit Values (TLVs®) of the American Conference of Governmental Industrial Hygienists (ACGIH®). These

outdated standards include about 450 chemicals. OSHA has promulgated only about 30 new chemical standards in its 46-year history.

OSHA attempted to update its outdated chemical standards in 1989 in a single rulemaking. However, the rule was vacated by the federal court, finding that OSHA had not proven that each new PEL would eliminate significant risk and be feasible in each effected industry. OSHA has addressed this dilemma, in part, by posting more current exposure limits on its website including 1) NIOSH recommended exposure limits (RELs), 2) ACGIH® Threshold Limit Values (TLVs®), and 3) California Division

of Occupational Safety and Health (Cal/OSHA) Permissible Exposure Limits (PELs).

Links to the tables are located at: https://www.osha.gov/dsg/annotated-pels/index.html. However, these more protective limits are not enforceable OSHA standards. In a letter to EPA Assistant Administrator James J. Jones, OSHA Director, David Michaels stated his view that given limitations

imposed on OSHA, TSCA gives EPA a means of regulating risk associated with methylene chloride and N-methyl pyrrolidone in paint removers and trichloroethylene in a more coordinated fashion in both consumer and

occupational settings. EPA is planning to complete work on the rules for these three chemicals by October and December of 2017.

Why is this important? There are more than 85,000 chemical substances on the EPA’s TSCA Inventory of Chemical Substances. More than 7,600 of

these chemicals were reported in volumes of 25,000 pounds or more as part of the 2012 Chemical Data Reporting (CDR) effort. The estimated number of occupational diseases in 2007 was 53,000 deaths and 463,000 non-fatal cases at a cost of $46 billion.

More on-the-job deaths are due to occupational diseases than injuries. About a third of the disease deaths are occupational cancers. Workers’ compensation covers less than 25 percent of these costs, so all members of society share the burden. President Obama remarked during the bill signing in explaining the need for TSCA reform, “The system was so complex,

it was so burdensome that our country hasn’t even been able to uphold a ban on asbestos, a known carcinogen that kills as many as 10,000 Americans every year.”

What are the important reforms in the revised TSCA? Under the new law:

- EPA has a mandatory duty to evaluate chemicals with clear and enforceable deadlines.

- Chemicals must be assessed against risk-based safety standard.

- EPA must consider susceptible and highly exposed populations including workers.

- EPA must move to regulatory action on chemicals. Unreasonable risks must be eliminated/reduced.

- EPA will require that the OSHA hierarchy of controls is used.

- EPA is authorized to move quickly to ensure development of chemical risk assessments when needed.

The summaries below address key provisions in the updated TSCA that

should impact worker safety and health. Section 3, Susceptible populations

EPA must identify populations that are disproportionately at risk either due to greater exposure or greater susceptibility to injury from a chemical. The new law identifies workers as one of the potentially exposed or susceptible populations that may be at greater risk. An exposure to a susceptible population is considered in setting priorities and in risk assessments.

Populations with Greater Susceptibility or Exposure

• Infants • Workers • Pregnant • Women • Children • The Elderly

Section 5, New Chemicals

There is a new requirement that EPA must make an affirmative finding on the safety of a new chemical or significant new use of an existing chemical before it is allowed into the marketplace. EPA can still take a range of actions to address potential concerns including restrictions, additional testing of the chemical, or a ban for one or more use. EPA is also updating its regulations to coincide with changes to the OSHA Hazard Communication Standard (29 CFR 1910.1200) to conform with the Globally

Harmonized System of Classification and Labeling of Chemicals (GHS), changes to the OSHA Respiratory Protection Standard (29 CFR 1910.134), and changes to the NIOSH respirator certification requirements (42 CFR Part 84).

Section 5, Action to address unreasonable risks In its proposed rule, EPA has included that worker safety requirements shall be implemented consistent with the OSHA hierarchy of controls approach, where feasible. Under that hierarchy, an employer should attempt to eliminate or substitute hazardous chemicals and use engineering and administrative controls before requiring workers to use personal protective equipment.

Several aspects of Section 6 are relevant to workers; each is described below:

Chemicals already on the market

One of the most important reforms is to Section 6, which governs chemicals that are already on the market. The change addresses the limitations on EPA authority that prevented it from regulating asbestos and by implication, other chemicals. The new language requires EPA to regulate

a chemical based solely on health and environmental factors. The new law requires EPA to develop regulations on prioritization, risk assessment, and regulation of chemical substances and mixtures.

Priorities and risk assessments

EPA is directed to establish rules on setting priorities and conducting risk assessments. They expect these rules to be completed by mid-June 2017. Occupational exposures shall be considered in setting priorities and

conducting risk assessments. EPA is directed to initiate risk assessments

on at least 10 chemicals drawn from the EPA work plan for chemical assessments within 6 months, and then within 3.5 years ensure that risk assessments are being conducted for at least 20 high priority substances.

Preference in setting priorities is to be given to chemicals that have a high persistence and bioaccumulation score, identified as known human carcinogens and those that have high acute or chronic toxicity. Chemicals are evaluated against a new risk-based safety standard to determine

whether a chemical use poses an “unreasonable risk”. Risk evaluation

excludes consideration of costs or non-risk factors. Risk assessments will evaluate chemicals throughout their “life cycle”, from manufacture to disposal. EPA will use a weight of evidence approach in determining

risk. These risk assessments should also be invaluable for OSHA rulemaking

Section 6, Regulatory action

Once unreasonable risks to human health are identified, EPA must take final risk management action within two years, or four years if an extension is warranted. The decision to regulate or not is determined

based on the risk to susceptible groups and any restrictions must protect them. The amendment also removes the requirement in the original law that EPA must choose the “least burdensome” way of addressing the

risk posed by a chemical. This phrase was a major factor in the federal court ruling on the attempt by EPA to ban asbestos. The court effectively found that EPA had to prove it had analyzed every conceivable way of

restricting asbestos and had chosen the one that was “least burdensome” to industry. Under the new law, EPA must conduct both a cost/benefit and a cost/effectiveness analysis of any proposed restrictions that includes the impact on the economy.

Let’s take this opportunity to reduce occupational disease!

https://tools.niehs.nih.gov/wetp/public/hasl_get_blob.cfm?ID=10883

Handbook of Solvents

Chemical Hazards Handbook

Product Intake Fraction (PiF) Framework

Pocket Guide for Chemcial Hazards

Injury Mechanisms

Examples or Case Studies of Incident Scenarios

The Disaster Management Cycle

A Chemical Incident Management Structure

Risk Assessment

Communication about Risk Assessment and Training

Prevention: Protection Layers, Scenario Analysis and Impact Assessment

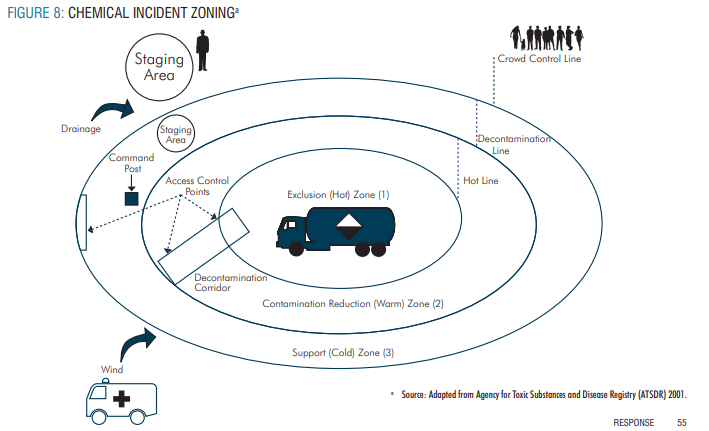

Control of contaminated environment

Emergency planning and response

Inspection of hazardous sites and transporation

Identificaiton and protection of vulnerable populations, public education and awareness

Global Agreements

Regional Agreements

National Laws

International Tools

Environmental monitoring, detection and alert

Terminate Release, Prevent Spread of Contamination and Limit Exposure

Register all exposed individuals and collect samples to estimate exposure