Every time I would cut this irrigation valve on a drip nozzle or emitter would shoot off into space. For many months, I kept kicking around in my head “What in the world is going on with this drip line?”

Then, I remembered my time in commercial landscape installation days and one of the key lessons learned by my boss. David said, “Always, Always, Always, remember to install a drip valve assembly in this order: Valve, Filter, then Pressure Reducer.”

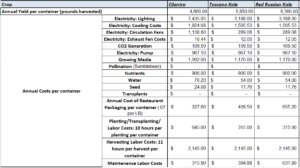

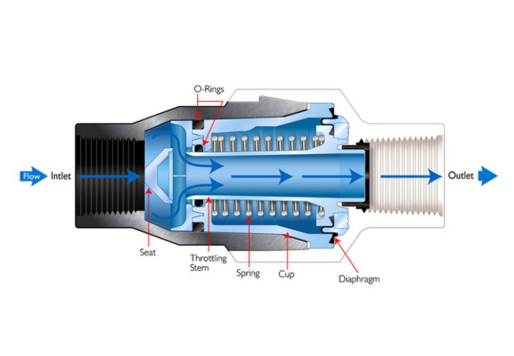

How could I forget! Well, maybe because it had been 10 years since I installed my last one… That was the answer. I had installed the valve and the filter, but the pressure reducer was missing. The main line was a 1″ pipe, so I know the pressure was probably 70 PSI or so. No wonder the nozzles on the spray stakes and the emitters were continuing to pop off. There a few different types of pressure reducers, AKA pressure regulators. The ones I like to use for drip irrigation assemblies are 50PSI. Meaning that no matter what pressure the mainline might be putting out, this device will bring the pressure down to a steady 50PSI

It is about the most aggravating thing ever. You see there is water shooting up, so you go and put in an emitter or you put in a new nozzle in the spray stake. Only to find that the next day or shortly after, a different one pops off. AGH! Seriously!

So, I dug all around the valve, filter and the pipe on each side. I cleared the dirt around it so it looked neat and was easy to work with. I have found through experience and training that it is crucial to clear away dirt from the work area so that when you go into to do the work, you don’t have to end up flushing the lines or having clogged nozzles and emitters later. That happens if dirt gets into the drip line.

You don’t want to put the pressure reducer before the valve meaning closest to the main line because you need the water pressure to close and open the valve quickly. Normally all of this, the valve and it’s electrical connections, the water filter and then pressure reducer all fit inside of a 18″ rectangle valve box.

For bonus points, I sometimes will find a shovel or two of gravel and put it in the valve box to help keep things nice and clean.